Responds to sudden steam shots. It has a large evaporation surface and steam volume.

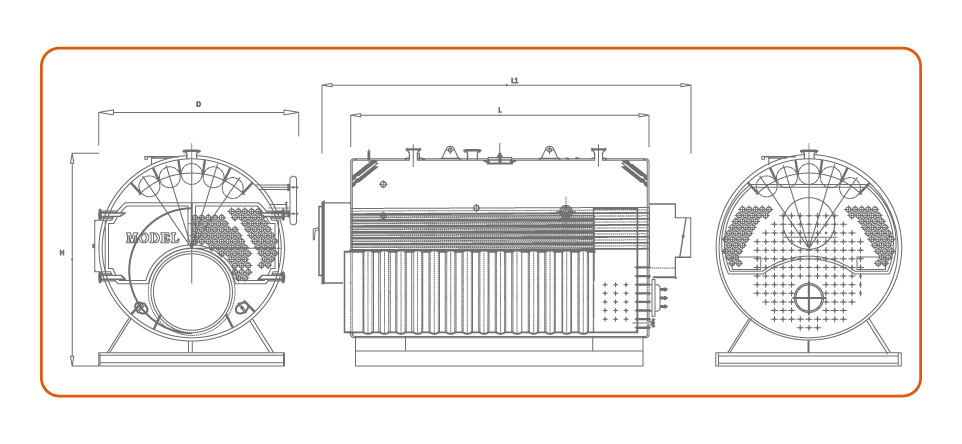

Technical Drawing:

Explanations:

1- It is designed and manufactured to meet the needs of industrial facilities such as food, textile, chemical industry and for heating large residential facilities.

2- It can produce between 300 kg/h and 10,000 kg/h capacities.

3- Boilers are fire tubes and tubes are welded to the tubesheet.

4- During design compatible sheet metal is choosed (P235, P265, P295, P355) to stand with high pressures.

5- The boilers are subjected to hydrostatic pressure test which is 1.5 times the operating pressure. However, the working pressure range is between (1-15) bar for our serial production. For higher pressure you can contact with us.

6- Responds to sudden steam shots. It has a large evaporation surface and steam volume.

7- It is manufacutred with corrugated furnace, and puddle tubes sheet.

8- In Solid fuels units there is perfect harmonious between the scotch steam boilers and the front furnaces.

9- In solid fuel boilers; The combustion air fan and chimney fan are full inverter automation.

10- Boiler tubes are high pressure special pipes of drawing seamless steel.

11- It is suitable for solid fuels (coal, pellets …) usage, long life and high efficiency.

12- Solid fuels boilers can be turn into liquid-gas fueled by install burner on it.

13- It balances the heat differences thanks to its design, it shows resistance to high pressure.

14- Due to 3-pass design, the heat transfer to the water increased by increasing the waiting time of flame inside the boiler.

15- The boiler body is painted with heat resistant boiler paint and it is insulated with rock wool.

16- Insulation is covered with colored galvanized sheet or aluminum which provide beautiful appearance.

17- The fuel cap is insulated with fire resistance concrete stand up to 1000° C.

18- The covers are produced as double-walled and heat insulation is minimized by using heat insulation wool between the two walls.

19- The fume escape is prevented by using ceramic wick gaskets on the covers.

20- Welding operations are performed by our certified welders according to WPQR.

21- In order to improve the efficiency of your boiler, you can add an economizer from our products.

22- For high capacity boilers, double furnace can be assembled.

23- Our boilers can be delivered as a complete package with its equipment and automation system.

24- According to your request our company can manufacture your product under control of “Türk Lloydu” or similar independent organizations.

25- For the boilers which is hard to shipping or enterance it to its rooms, on-site manufacturing is carried out at factory standards.

26- It is certified by TS 497 - TS 377 - TS EN 303-5-3-1.

27- It is manufactured in accordance to EN 12953 standards.

28- It has Turkish Standards Institute (TSE) efficiency certificate.

29- It has ISO and CE (2016/426/EU) and (2014/68/EU) certificates.

30- It has 2 years Modelsan warranty.

Front Furnace (Water Tube Boiler) and Stoker System:

1- It burns solid fuels such as lignite, pellet, powder coal (0.5 - 30 mm), hazelnut shell and apricot, olive oil with high efficiency.

2- Since it provides a complete combustion, it starts up the system in a very short time. Environmentally friendly, high efficiency, easy to operate.

3- It is manufactured in order to required capacity and it is easy to installed to boilers.

4- It is the most suitable system for high capacities where the manual loading is difficult.

5- In steam boilers, due to its high performance, it responds to the desired capacity.

6- Less moving parts of the system reduces the systematic problems.

7- Firing pot is manufactured from special steel sheets which is resistant to high temperature.

8- Double pot can be manufactured as required.

Automation System:

1- Boiler feed pump control

2- Water level controlled

3- Stoker controlled

4- Flue gas temperature controlled

5- Steam temperature control

6- Hazard warning light

7- Low water level control

8- High water level control

9- Combustion fan controlled

10- Suction fan controlled